RETROFIT / MODIFICATION / IMPROVEMENTS

Machine retrofitting is made when the equipment gives the company a financial return. Specifically this can be revision, modification and improvement of the equipment. It can provide our client a chance to use the equipment for a longer period as well as a lower investment compared to the price of new equipment.

There is a guarantee and technical support for machine restoration and retrofitting. The financial return will be obtained with the increase in production, along with the time which the equipment runs and the reduction of wasted time generated by outdated equipment.

Restoration and retrofitting are options for companies which desire more productivity and a lower cost investiment.

- Large, medium and small equipment;

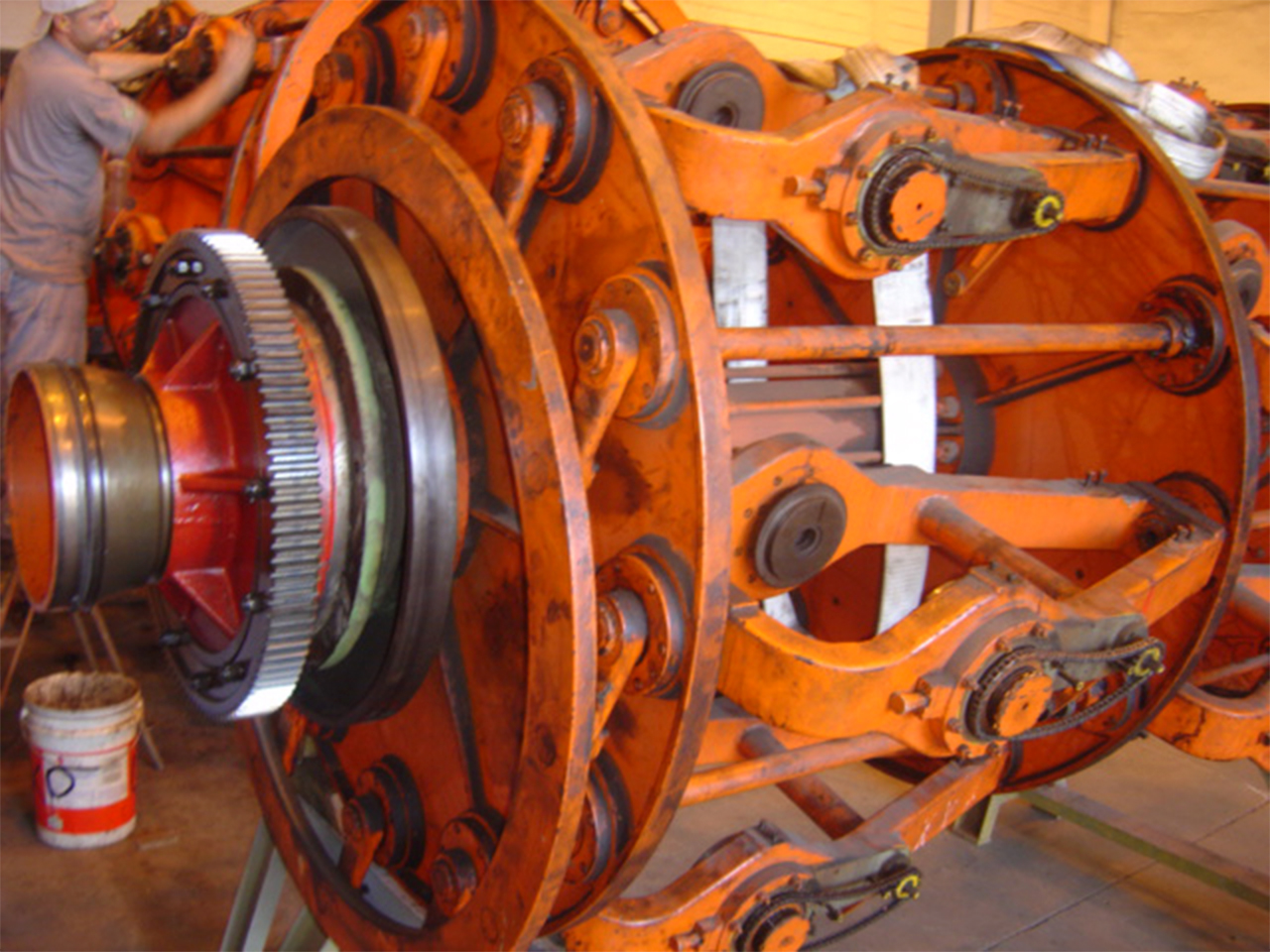

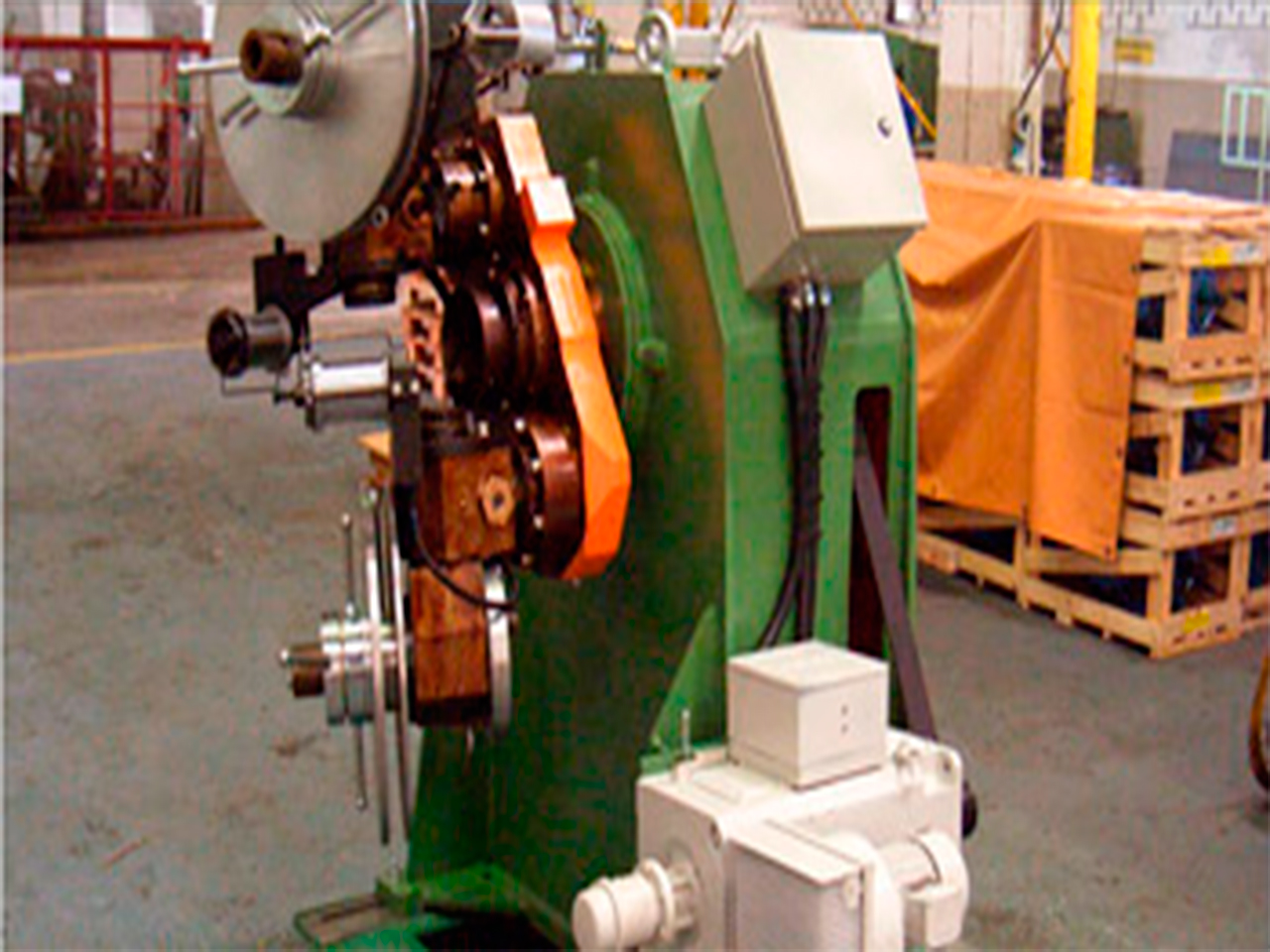

- Rotating equipment; ( Twist, Rigid, Drum,etc);

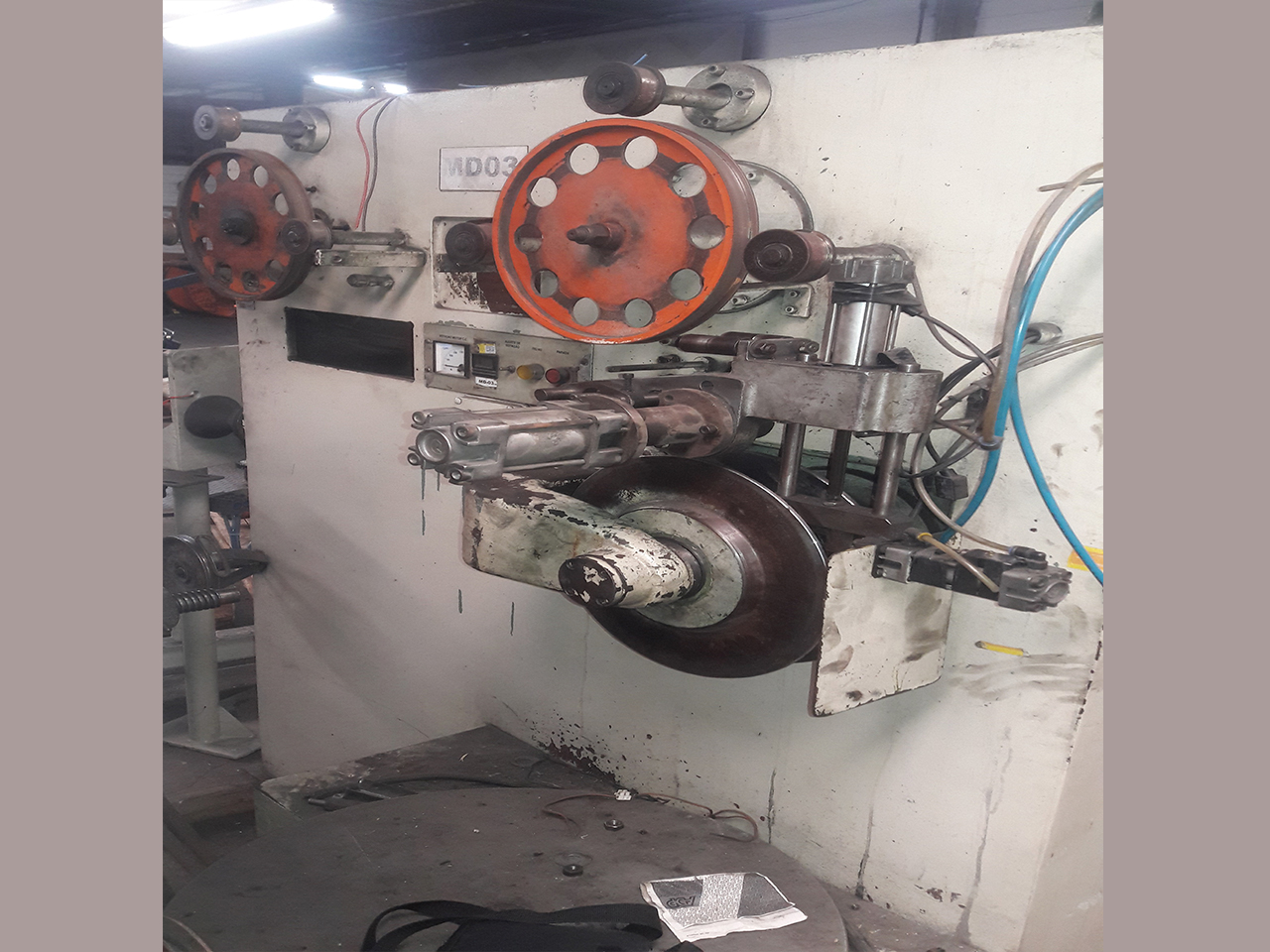

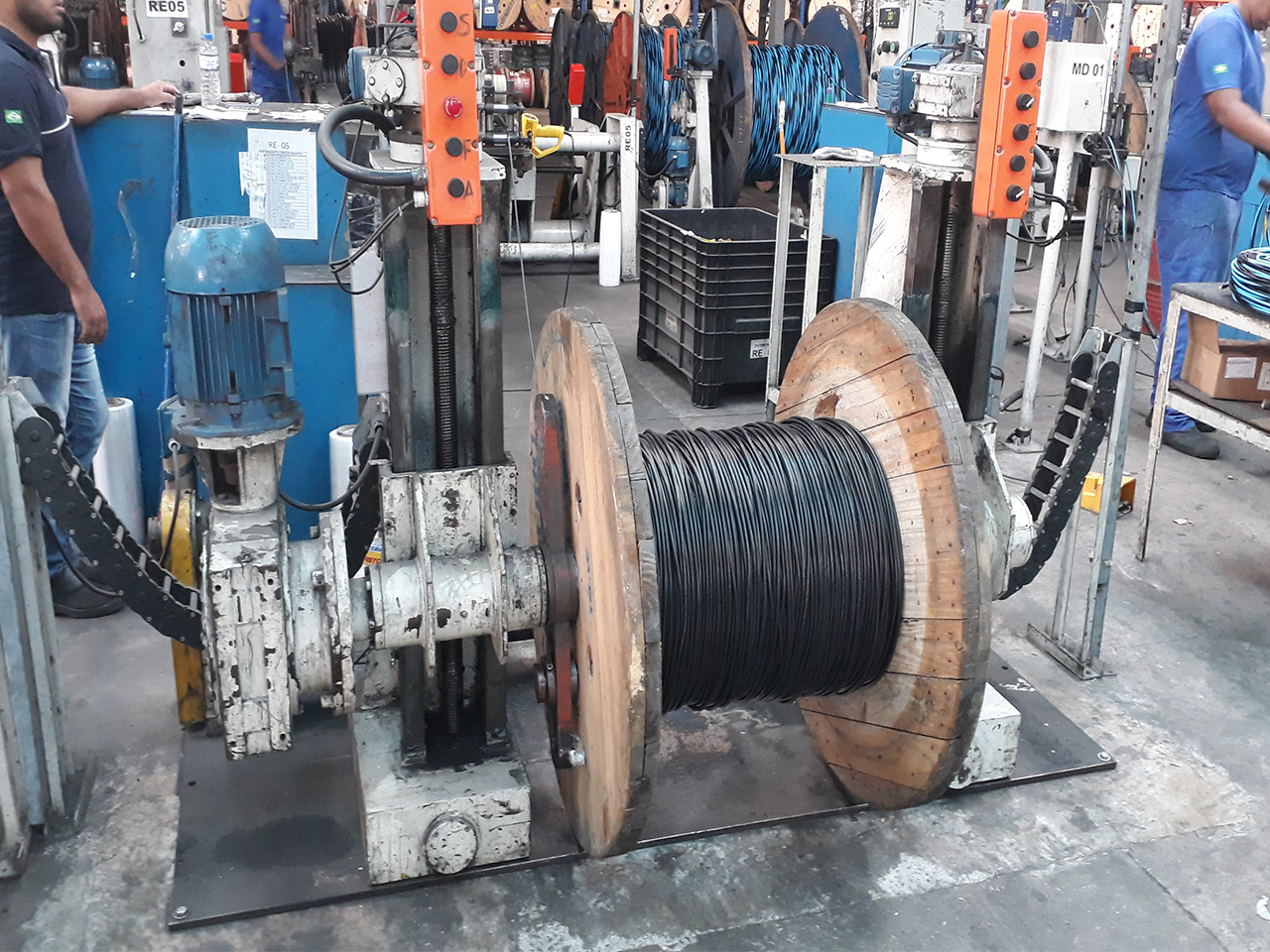

- Rewind lines and Extrusion lines;

- Extruder, Pay off, Take up, Caterpillar, Accumulator, etc;

- Development, modification and improvement in equipment;

- Project and development for mechanical, hydraulic and pneumatic systems;

- Assessment and restoration of gear units;

- Restoration of pulleys, shafts; (aluminium, steel and cast iron bars, etc);

- Application of coating on worn out areas of various parts and machining.