DOUBLE CONE PAY-OFF

Double Cone pay-off is the most used part in extrusion lines due to its speed and rapid bobbin exchange system. It works without interrupting or slowing down the speed of the extrusion process

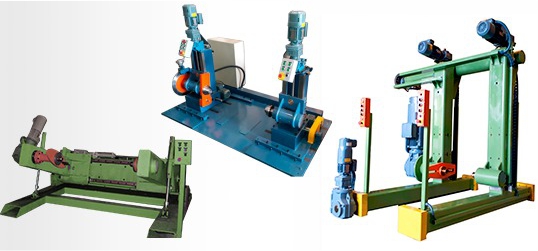

PAY-OFF / TAKE UP

This equipment is commonly used in extrusion lines, rewind lines, twist lines, etc. For each type of process is a specific model is recommended, such as: Portal, Traverse, Cantillever, Column, etc.

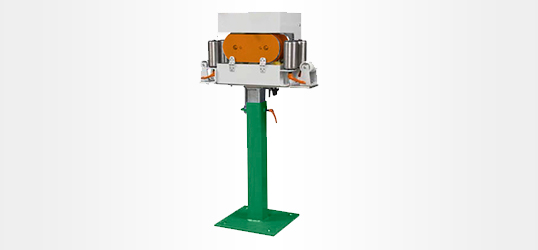

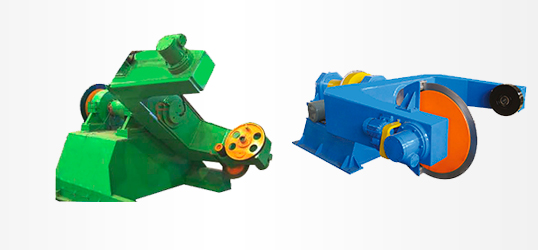

TENSION BRAKE / TENSIONER

This equipment usually works along with the Double Cone Pay-off in extrusion lines, rewind line and others. It has excellent tension control.

LENGTH COUNTER

Equipment model is similar to a Caterpillar, but has the advantage of reducing the slipping of the product with a belt, thereby ensuring precision in the measure.

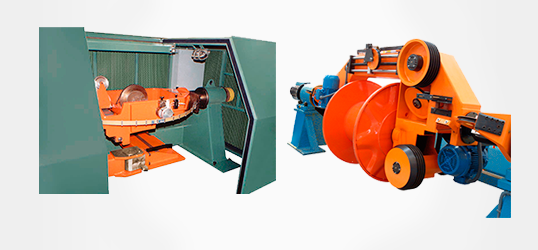

ACCUMULATOR

Cable Accumulator is used in extrusion lines to make the bobbin exchange without interrupting the production process or reducing the speed of the line. It can be assembled at the beginning and at the end of the line (horizontal or vertical), in a platform above the line or on the floor.

CATERPILLAR

Essential equipment for an extrusion line, controls the traction of the product and a constant line speed. The Caterpillar has different sizes depending on the weight, speed and diameter of the cable.

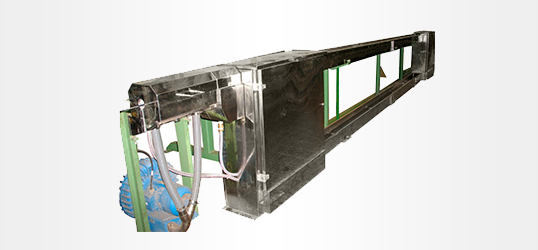

COOLING TROUGH

Cooling Trough is fabricated in stainless steel, depending on the type of process. It can be manufactured as a fixed module, movable, with or without pulleys for reshipment of the cables.

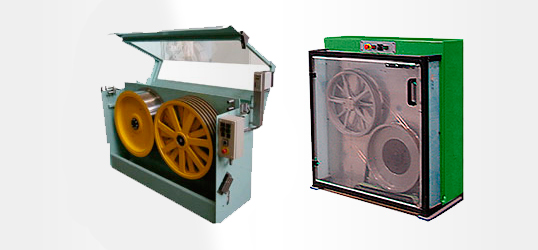

CAPSTAN

Capstan can be used in extrusion lines for smaller diameter cables. It is normally integrated at the end of the line. For twist lines the Capstan has a pulley diameter from 1-3 meters, depending on the type of process.

PACK COILER

This equipment is an excellent option to make rolls of 100 meters with high production capacity. The equipment is assembled with a detector for insulation failure, length counter, automatic cutter, with or without turntable to receive 4 rollers, with or without a box.

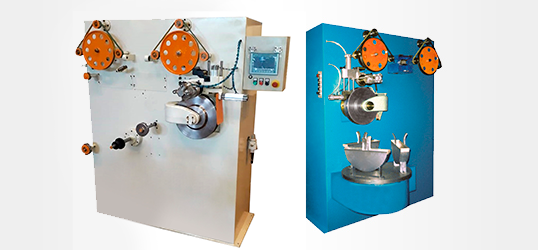

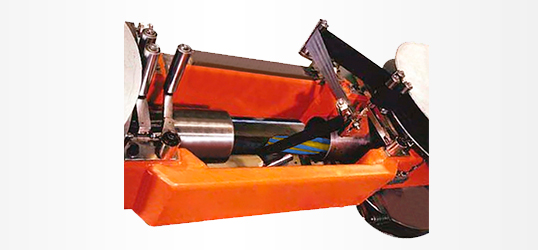

TAPE APPLICATOR

Various models with different characteristics are available for each type of process, including: concentric, tangential and longitudinal. It is used in extrusion lines in tandem and twist lines.

DRUM TWISTER

Drum Twister is an equipment used in different processes. It can be used with pay-off, take-up, energy cables, telecommunication cables, etc.

DOUBLE TWIST

The Double Twist is an excellent equipment for twisting flexible, rigid cables (with or without insulation) and control and instrumentation cables.

DOUBLE TAKE UP

Double Take up is used in an extrusion line for high speed production. It works totally independent in the line and has two versions, semi-automatic and automatic. Bobbin exchange occurs without stopping the production line or reducing its speed.

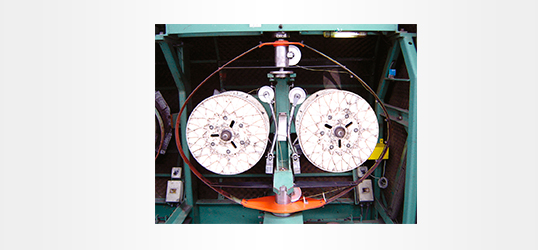

MOTORIZED DOUBLE PAY OFF

Motorized Double Pay Off is an equipment used in twist lines to unwind wires with or without insulation. The main feature of the equipment is tension control.

CABLE DRYER

Cable Dryer is used in extrusion lines for various cable diameters and processes.

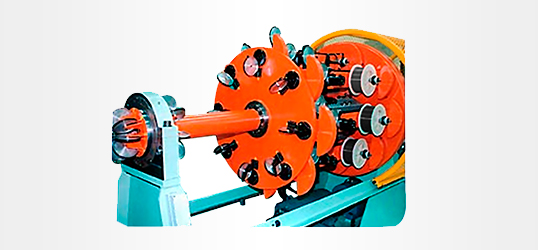

SCREENING

Screening is used for wire application and can work with a tape applicator in the same line. This equipment uses up to 44 bobbins with a wire diameter 0,4mm – 1,5mm.

TWINNER

Twinner is an equipment designed to gather wire from two or more bobbins assembled in modules.This equipment is used for telephone cables and its configuration allows to gather many pairs of insulated wires.

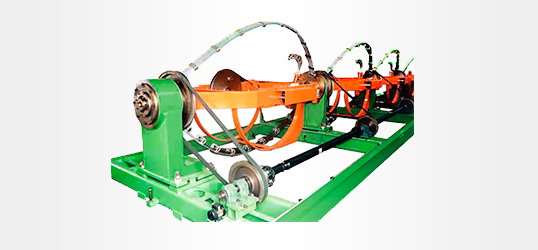

PLANETARY STRANDER

Planetary Strander is used for manufacturing OPGW and ACSR cables. This equipment has a back twist system and excellent voltage control.

BOW TWIST

Bow Twist is an equipment with high operational performance and productivity to gather insulated cables. It is widely used for the manufacture of multiplex cables in the configuration of (1+3 or 1+4 bobbins).

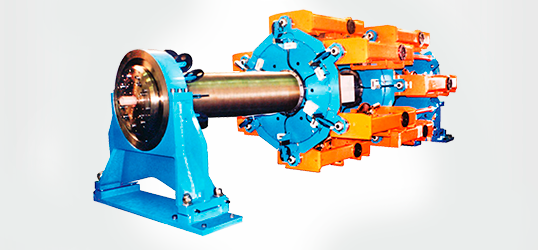

RIGID STRANDER

Rigid Strander is an line used to manufacture cables with larger sections. It has an effective wire tension control system and an excellent product formation.